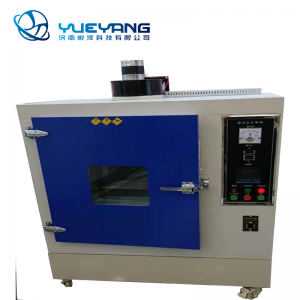

Ikamelo Lokushisa Elihlala Njalo le-YYS-100 kanye Nomswakama (0℃)

Isifinyezo:

| Igama Lezinsimbi Zomculo | Igumbi lokuhlola lokushisa nomswakama elingaguquki elihleliwe | |||

| Inombolo Yemodeli: | YYS-100 | |||

| Ubukhulu be-studio yangaphakathi (D*W*H) | 400×450×550mm | |||

| Ubukhulu obuphelele (D*W*H) | 9300×9300×1500mm | |||

| Isakhiwo sezinsimbi | Ukuma kwegumbi elilodwa | |||

| Ipharamitha yobuchwepheshe | Ibanga lokushisa | 0℃~+150℃ | ||

| Isiqandisi sesigaba esisodwa | ||||

| Ukushintshashintsha kwezinga lokushisa | ≤±0.5℃ | |||

| Ukufana kwezinga lokushisa | ≤2℃ | |||

| Izinga lokupholisa | 0.7~1℃/umzuzu(I-1965)isilinganiso) | |||

| Izinga lokushisa | 3~5℃/umzuzu(I-1965)isilinganiso) | |||

| Ububanzi bomswakama | 10%-98%RH(I-1965)Hlangana nokuhlolwa okuphindwe kabili okungu-85) | |||

| Ukufana komswakama | ≤±2.0%RH | |||

| Ukuguquguquka komswakama | +2-3%RH | |||

| Ukuhambelana kwezinga lokushisa nomswakama Umdwebo wejika |  | |||

| Ikhwalithi yezinto ezibonakalayo | Izinto zegumbi langaphandle | Isifutho sikagesi sensimbi egoqiwe ebandayo | ||

| Izinto zangaphakathi | I-SUS304 Insimbi Engagqwali | |||

| Izinto zokuvimbela ukushisa | Ukotini wokushisa ingilazi omuhle kakhulu ongu-100mm | |||

| Uhlelo lokushisa | i-heater | Isifudumezi sikagesi sepayipi lokushisa esiqeda ukushisa esisebenza ngensimbi engagqwali esingu-316L | ||

| Imodi yokulawula: Imodi yokulawula ye-PID, isebenzisa i-SSR engaxhumani nezinye izikhathi zokwandisa i-pulse (i-solid state relay) | ||||

| Isilawuli | Ulwazi oluyisisekelo | Isilawuli sokushisa kanye nomswakama esilungiselelwayo se-TEMI-580 True Color Touch | ||

| Ukulawulwa kohlelo amaqembu angu-30 ezingxenye eziyi-100 (inani lezingxenye lingalungiswa ngokungahleliwe futhi linikezwe iqembu ngalinye) | ||||

| Indlela yokusebenza | Setha inani/uhlelo | |||

| Imodi yokusetha | Okokufaka ngesandla/okufaka kude | |||

| Setha ububanzi | Izinga lokushisa: -199℃ ~ +200℃ | |||

| Isikhathi: 0 ~ 9999 amahora/umzuzu/umzuzwana | ||||

| Isilinganiso sesisombululo | Izinga lokushisa: 0.01℃ | |||

| Umswakama: 0.01% | ||||

| Isikhathi: 0.1S | ||||

| Okokufaka | Ukumelana neplatinum ye-PT100 | |||

| Umsebenzi we-accessory | Umsebenzi wokubonisa i-alamu (imbangela yephutha ngokushesha) | |||

| Umsebenzi we-alamu yokushisa okulinganiselwe okuphezulu nokuphansi | ||||

| Umsebenzi wesikhathi, umsebenzi wokuzihlola. | ||||

| Ukutholwa kwedatha yokulinganisa | Ukumelana neplatinum ye-PT100 | |||

| Ukucushwa kwengxenye | Uhlelo lwesiqandisi | i-compressor | Iyunithi ye-compressor yaseFrance yokuqala ethi “Taikang” evalwe ngokuphelele | |

| Imodi yokuqandisa | Isiqandisi sesigaba esisodwa | |||

| Isiqandisi | Ukuvikelwa kwemvelo R-404A | |||

| Hlunga | I-AIGLE (e-USA) | |||

| i-condenser | Uhlobo "lwe-POSEL" | |||

| Isihwamukisi | ||||

| I-valve yokwandisa | I-Danfoss yokuqala (eDenmark) | |||

| Uhlelo lokujikeleza komoya | Ifeni yensimbi engagqwali ukuze kuzuzwe ukujikeleziswa komoya okuphoqelelwe | |||

| Injini yokuhlukanisa ye-Sino-foreign joint venture "Heng Yi" | ||||

| Isondo lomoya elinamaphiko amaningi | ||||

| Uhlelo lokuhambisa umoya lujikeleza kanye | ||||

| Isibani sefasitela | I-Philips | |||

| Okunye ukucushwa | Isibambi Sesampula Esisuswayo Sensimbi Engagqwali 1 isendlalelo | |||

| Imbobo yokuhlola ikhebula engu-Φ50mm 1 pcs | ||||

| Ifasitela nelambu lokuhlola ingilazi elisebenza ngogesi eliyimbobo elikhipha iqhwa | ||||

| Isondo elijikelele elisekhoneni eliphansi | ||||

| Ukuvikelwa kokuphepha | Ukuvikelwa kokuvuza | |||

| Isivikelo se-alamu esithi “Rainbow” (Korea) esishisa ngokweqile | ||||

| I-fuse esheshayo | ||||

| Isivikelo se-compressor sokucindezela okuphezulu nokuphansi, ukushisa ngokweqile, isivikelo somsinga ongaphezulu | ||||

| Ama-fyuzi omugqa kanye nama-terminal agcwele isihenqo | ||||

| Izinga lokukhiqiza | GB/2423.1;GB/2423.2;GB/2423.3;GB/2423.4;IEC 60068-2-1; I-BS EN 60068-3-6 | |||

| Isikhathi sokuthumela | Izinsuku ezingu-30 ngemuva kokufika kwenkokhelo | |||

| Sebenzisa indawo | Izinga lokushisa: 5℃ ~ 35℃, umswakama ohlobene: ≤85%RH | |||

| Isayithi | 1.Izinga lomhlabathi, umoya omuhle, ayinayo igesi evuthayo, eqhumayo, ebolile kanye nothuli2.Akukho mthombo wemisebe enamandla kagesi eduzeShiya isikhala esifanele sokulungisa eduze kwedivayisi | |||

| Isevisi yangemva kokuthengisa | 1. Isikhathi sewaranti yemishini sonyaka owodwa, ukulungiswa kwempilo yonke. Iwaranti yonyaka owodwa kusukela ngosuku lokulethwa (ngaphandle komonakalo obangelwe yizinhlekelele zemvelo, ukungalingani kwamandla, ukusetshenziswa kabi kwabantu kanye nokulungiswa okungafanele, inkampani imahhala ngokuphelele). Ngezinsizakalo ezingaphezu kwesikhathi sewaranti, kuzokhokhiswa imali yezindleko ezifanayo. 2. Ekusetshenzisweni kwemishini ngesikhathi senkinga ukuze iphendule zingakapheli amahora angama-24, futhi inikeze onjiniyela bokulungisa ngesikhathi esifanele, abasebenzi bezobuchwepheshe ukuthi babhekane nenkinga. | |||

| Uma imishini yomhlinzeki iphuka ngemva kwesikhathi sewaranti, umhlinzeki kufanele ahlinzeke ngensizakalo ekhokhelwayo. (Imali iyasebenza) | ||||

Bhala umlayezo wakho lapha bese uwuthumela kithi