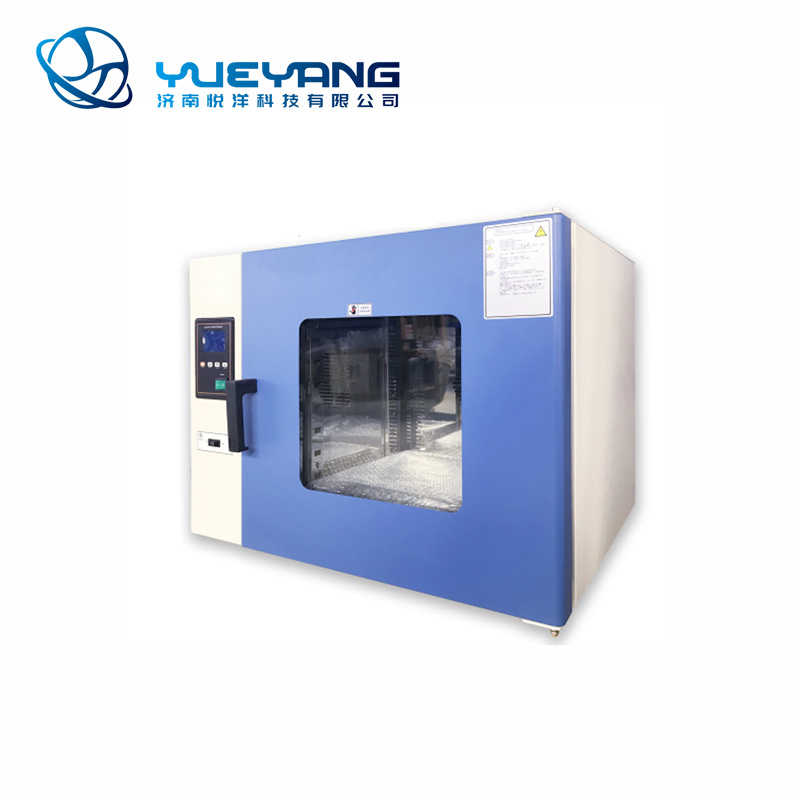

Ihhavini Yokushisa Okuphezulu ye-YYP-252

Isebenzisa ukushisa okuphoqelelwe eceleni komoya oshisayo, uhlelo lokufutha lusebenzisa ifeni ye-centrifugal enama-blade amaningi, inezici zomoya omkhulu, umsindo ophansi, izinga lokushisa elifanayo esitudiyo, insimu yokushisa ezinzile, futhi igwema imisebe eqondile evela emthonjeni wokushisa, njll. Kukhona ifasitela lengilazi phakathi komnyango nesitudiyo ukuze kubhekwe igumbi lokusebenza. Ingxenye ephezulu yebhokisi inikezwe i-valve yokukhipha eguquguqukayo, izinga layo lokuvula elingalungiswa. Uhlelo lokulawula lugxile egumbini lokulawula ohlangothini lwesobunxele lwebhokisi, olulungele ukuhlolwa nokugcinwa. Uhlelo lokulawula izinga lokushisa lusebenzisa i-digital display adjuster ukulawula izinga lokushisa ngokuzenzakalelayo, ukusebenza kulula futhi kunembile, ukushintshashintsha kwezinga lokushisa kuncane, futhi kunomsebenzi wokuvikela izinga lokushisa ngokweqile, umkhiqizo usebenza kahle ekushiseni, ukusetshenziswa okuphephile nokuthembekile.

1. Ububanzi bokulungiswa kokushisa: izinga lokushisa legumbi -300℃

2. Ukuguquguquka kwezinga lokushisa: ±1℃

3. Ukufana kwezinga lokushisa: ± 2.5%

4. Ukumelana nokushisa: ≥1M (isimo sokubanda)

5. Amandla okushisa: ahlukaniswe ngama-grade amabili angu-1.8KW kanye no-3.6KW

6. Ukunikezwa kwamandla: 220±22V 50±1HZ

7. Usayizi wesitudiyo: 450×550×550

8. Izinga lokushisa eliphakathi: 5 ~ 40℃, umswakama ohlobene awudluli ku-85%