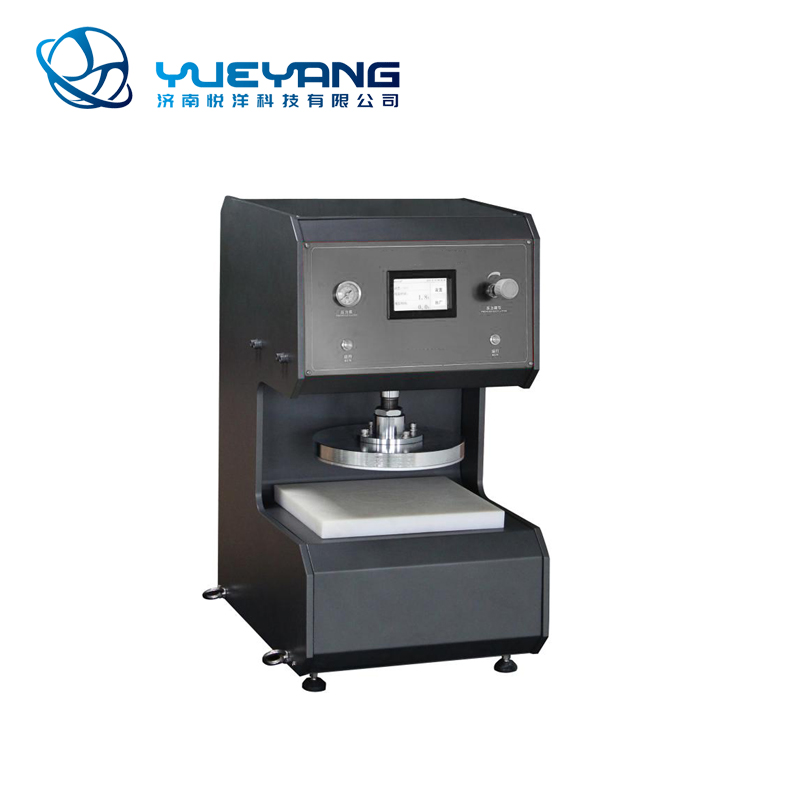

YY02 Umsiki Wesampula Womoya

Isetshenziselwa ukwenza amasampula ezimo ezithile zezindwangu, isikhumba, izinto ezingezona ezelukiwe nezinye izinto. Imininingwane yamathuluzi ingaklanywa ngokwezidingo zomsebenzisi.

1. Nge-dee yommese engenisiwe, unqenqema lokwenza amasampula ngaphandle kwe-burr, impilo eqinile.

2. Ngenzwa yokucindezela, ingcindezi yokusampula kanye nesikhathi sokucindezela kungalungiswa futhi kusethwe ngokunganaki.

3 Ngephaneli ekhethekile ye-aluminium engenisiwe, okhiye bensimbi.

4. Ifakwe umsebenzi wokuqalisa izinkinobho ezimbili, futhi ifakwe amadivayisi amaningi okuvikela ukuphepha, vumela opharetha ukuthi aqiniseke ukuthi uyawasebenzisa.

1. Ukushaya kweselula: ≤60mm

2. Ukucindezela okukhulu kokukhipha: ≤5 amathani

3. Umfutho womoya osebenzayo: 0.4 ~ 0.65MPa

4. Ukunemba kokulungiswa kwengcindezi yomoya: 0.005Mpa

5. Ububanzi bokusethwa kwesikhathi sokubamba ingcindezi: 0 ~ 999.9s, isixazululo 0.1s

6. Uhlu lwamathuluzi asekelayo (okujwayelekile ngamasethi amathathu)

| isikhunta sommese Igama | Ubuningi | Usayizi Wesampula | Imisebenzi |

| Idayi yokusika indwangu | 1 | 5mm×5mm(L×W) | Amasampula alungiselelwe ukuhlolwa kwe-formaldehyde kanye ne-pH. |

| Idayi yokusika i-Gram | 1 | Φ112.8mm | Amasampula enzelwa ukubala isisindo sendwangu ngamamitha-skwele. |

| Gqoka ithuluzi lokulinganisa elingamelana ne-Gqoka | 1 | Φ38mm | Kwenziwe amasampula okuhlolwa kokumelana nokuguguleka kweMardener kanye nokuhlolwa kokubulala. |

7. Isikhathi sokulungiselela isampula: <1min

8. Usayizi wethebula: 400mm×280mm

9. Usayizi wepuleti lokusebenza: 280mm × 220mm

10. Amandla namandla: AC220V, 50HZ, 50W

11. Ubukhulu: 550mm×450mm×650mm(L×W×H)

12. Isisindo: 140kg

1. Umsingathi--- Isethi eyi-1

2. Ukufanisa ithuluzi lokufa-- Amasethi ama-3

3. Amapuleti Okusebenza ---1 Ama-PC

1. Iphampu yomoya ethule esezingeni eliphezulu--1 PC

2.Ukusika okunamathiselwe kwedayi

Okunamathiselwe

| Into | Ukusika idayisi | Usayizi Wesampula (L×W)mm | Isaziso |

| 1 | Idayi yokusika indwangu | 5×5 | Amasampula asetshenziswe ekuhlolweni kwe-formaldehyde kanye ne-pH. |

| 2 | Idayi yokusika i-Gram | Φ113mm | Kwenziwa amasampula ukuze kubalwe isisindo sendwangu ngamamitha-skwele. |

| 3 | Gqoka ithuluzi lokulinganisa elingamelana ne-Gqoka | Φ38mm | Amasampula asetshenziselwa ukuhlolwa kokumelana nokuguguleka kweMardener kanye nokuhlolwa kokubulala. |

| 4 | Gqoka ithuluzi lokulinganisa elingamelana ne-Gqoka | Φ140mm | Amasampula asetshenziselwa ukuhlolwa kokumelana nokuguguleka kweMardener kanye nokuhlolwa kokubulala. |

| 5 | Ithuluzi lokuhlola isikhumba eliyi-die⑴ | 190×40 | Amasampula asetshenziswa ukunquma amandla okunamathela kanye nobude besikhumba. |

| 6 | Ithuluzi lokuhlola isikhumba eliyi-die⑵ | 90×25 | Amasampula asetshenziswa ukunquma amandla okunamathela kanye nobude besikhumba. |

| 7 | Ithuluzi lokuhlola isikhumba eliyi-die⑶ | 40×10 | Amasampula asetshenziswa ukunquma amandla okunamathela kanye nobude besikhumba. |

| 8 | Ukudiliza amandla okusika idayi | 50×25 | Isampula evumelana ne-GB4689.6 yenziwe.

|

| 9 | Ithuluzi lokudweba nge-strip | 300×60 | Isampula evumelana ne-GB/T3923.1 yalungiswa. |

| 10 | Ithuluzi lokwelula lifa ngokubamba isampula | 200×100 | Isampula evumelana ne-GB/T3923.2 yalungiswa. |

| 11 | Isikhunta sommese esiklabalala ngesimo sebhulukwe | 200×50 | Isampula evumelana ne-GB/T3917.2 yalungiswa. Idayi yokusika kufanele ikwazi ukwelula ububanzi besampula iye enkabeni ye-incision engu-100mm. |

| 12 | Ithuluzi lokudabula iTrapezoidal | 150×75 | Isampula evumelana ne-GB/T3917.3 yalungiswa. Idayi yokusika kufanele ikwazi ukwelula ubude besampula phakathi nendawo yokusikwa okungu-15mm. |

| 13 | Ithuluzi lokudabula elinomumo wolimi | 220×150 | Isampula evumelana ne-GB/T3917.4 yalungiswa.

|

| 14 | Ithuluzi lokudabula i-Airfoil | 200×100 | Isampula evumelana ne-GB/T3917.5 yalungiswa.

|

| 15 | Idayi yommese ukuze ithathwe njengesampula ephezulu | Φ60mm | Isampula evumelana ne-GB/T19976 yalungiswa. |

| 16 | I-strip sampling die | 150×25 | Isampula evumelana ne-GB/T80007.1 yalungiswa. |

| 17 | Thunga uqede ukusika idayisi | 175×100 | Isampula evumelana ne-FZ/T20019 yalungiswa. |

| 18 | I-pendulum yadabula isikhunta sommese | 100×75 | 制取符合GB/T3917.1试样.

|

| 19 | Idayi yokuthatha amasampula ehlanziwe | 100×40 | Isampula evumelana ne-GB/T3921 yalungiswa. |

| 20 | Idayi yokusika evikela ukuguguleka enamasondo amabili | Φ150mm | Isampula evumelana ne-GB/T01128 yalungiswa. Imbobo engaba ngu-6mm inqunywa ngqo maphakathi nesampula. Imbobo ayivalwanga ukuze kube lula ukususwa kwamasampula asele. |

| 21 | Isikhunta sokusika ibhokisi lokubhoboza | 125×125 | Isampula evumelana ne-GB/T4802.3 yalungiswa. |

| 22 | Idayi yommese ogoqekayo ongahleliwe | 105×105 | Isampula evumelana ne-GB/T4802.4 yalungiswa. |

| 23 | Ithuluzi lokuhlola amanzi | Φ200mm | Isampula evumelana ne-GB/T4745 yalungiswa. |

| 24 | Ithuluzi lokusebenza lokugoba | 250×25 | Isampula evumelana ne-GB/T18318.1 yalungiswa. |

| 25 | Ithuluzi lokusebenza lokugoba | 40×40 | Isampula evumelana ne-GB3819 yalungiswa. Okungenani amasampula amane kufanele alungiswe ngesikhathi esisodwa.

|