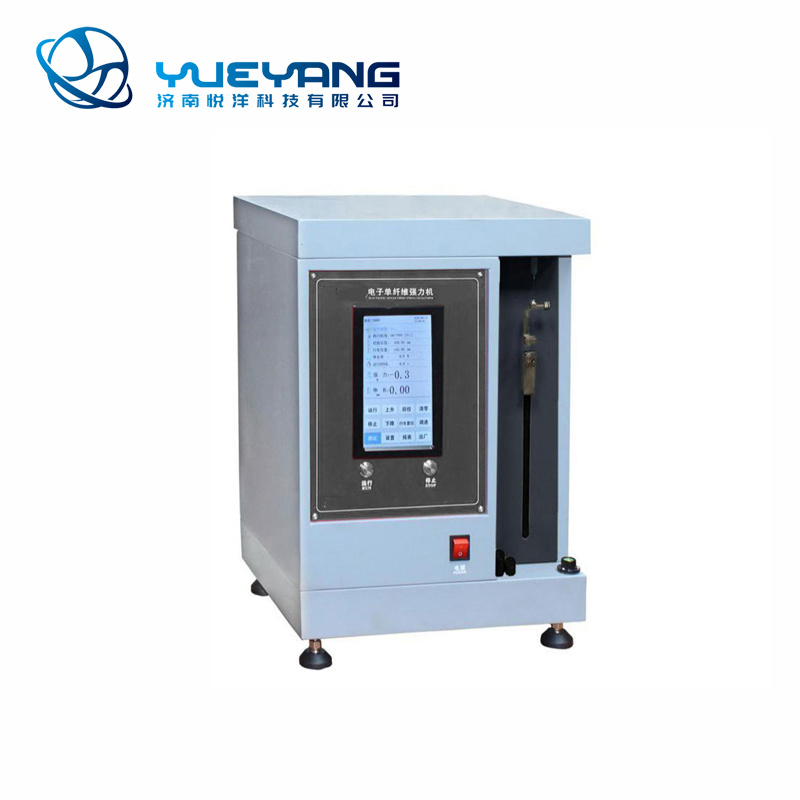

Isivivinyo Samandla Se-Single Fiber se-YY001Q (Isihlanganisi Somoya)

Isetshenziselwa ukuhlola amandla okuphuka, ukunwebeka lapho kuphuka, umthwalo lapho kunwebeka khona, ukunwebeka lapho kulayishwa khona, ukunwebeka kanye nezinye izakhiwo zefayibha eyodwa, ucingo lwensimbi, izinwele, ifayibha yekhabhoni, njll.

GB/T9997,I-GB/T 14337,GB/T13835.5,I-ISO5079,11566,I-ASTM D3822,BS4029.

1. Isibonisi sesikrini sokuthinta esinombala, ukulawula, isikhombikubona sesiShayina nesiNgisi, imodi yokusebenza kwemenyu;

2. Susa noma iyiphi idatha elinganisiwe, bese uthumela imiphumela yokuhlolwa kudokhumenti ye-Excel;

3. Umsebenzi wokuhlaziya isofthiwe: iphuzu lokuphuka, iphuzu lokuphuka, iphuzu lokucindezeleka, iphuzu lokuvuna, i-modulus yokuqala, ukuguqulwa kwe-elastic, ukuguqulwa kwepulasitiki, njll.

4. Izindlela zokuvikela ukuphepha: umkhawulo, ukulayisha ngokweqile, inani lamandla elibi, ugesi odlulayo, ukuvikelwa kwe-overvoltage, njll.;

5. Ukulinganiswa kwenani lamandla: ukulinganiswa kwekhodi yedijithali (ikhodi yokugunyazwa);

6. Ubuchwepheshe obuhlukile bokulawula ikhompyutha yokusingatha obunezindlela ezimbili, ukuze ukuhlolwa kube lula futhi kusheshe, imiphumela yokuhlolwa icebile futhi ihlukahlukene (umbiko wedatha, ijika,Amagrafu, imibiko);

7. Ukubopha nge-pneumatic kulula futhi kuyashesha.

1. Ukulinganisa ububanzi bamandla kanye nenani elincane lokukhomba: 500CN, inani lokukhomba: 0.01CN

2. Isixazululo somthwalo: 1/60000

3. Ukunemba kwenzwa yokuphoqelela: ≤±0.05%F·S

4. Ukunemba komthwalo womshini: ububanzi obuphelele bokunemba okungu-2% ~ 100% kwanoma yiliphi iphuzu ≤±0.5%

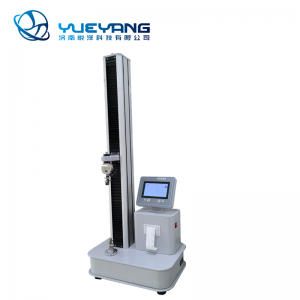

5. Isivinini sokunwebeka: ukulungiswa kwesivinini 2 ~ 200mm/min (ukusetha kwedijithali), isivinini esinqunyiwe 2 ~ 200mm/min (ukusetha kwedijithali)

6. Isixazululo sobude: 0.01mm

7. Ukwandiswa okukhulu: 200mm

8. Ubude besikhala: 5 ~ 30mm ukusethwa kwedijithali, ukubeka okuzenzakalelayo

9. Isitoreji sedatha: ≥izikhathi ezingu-2000 (hlola isitoreji sedatha yomshini)

10. Ukunikezwa kwamandla: AC220V±10%,50Hz

11. Ubukhulu: 400×300×550mm (L×W×H)

12. Isisindo: cishe ama-45kg

1. Umsingathi---Isethi eli-1

2. Layisha Iseli:500cN,0.01cN----Isethi eli-1

3. Ama-clamp:Uhlobo lomoya---Isethi eli-1

4. Isixhumi esibonakalayo sekhompyutha, isofthiwe yokusebenza ku-inthanethi--Isethi eyi-1

5. Isiqeshana sokunwebeka --- Isethi eyi-1

1.GB9997--Ukuhlolwa kwamandla okuphuka kwefayibha eyodwa

2.GB9997--Indlela yokunquma umthwalo wokuhlolwa kwe-fiber elastic eyodwa

3.GB9997--Indlela yokuhlola i-fiber elastic eyodwa yokwelulwa okuqinile

1.PC

2. Iphrinta

3. Thulisa iphampu