Izinsimbi Zokuhlola Ukupakisha Iphepha Nokuguquguquka

-

(China) Ikhabhinethi Yokuhlola Umbala Wemithombo Engu-6 Ekhanyayo (4 Foot)

- Ukusebenza Kwekhabhinethi Yesibani

- Ukukhanya kwelanga okwenziwe nge-hepachromic okuqashelwe yi-CIE, izinga lokushisa lombala elingu-6500K.

- Isikali sokukhanyisa: 750-3200 Luxes.

- Umbala wangemuva womthombo wokukhanya umpunga ongathathi hlangothi wokumunca. Uma usebenzisa ikhabethe lesibani, vimbela ukukhanya kwangaphandle ukuthi kungaveli kulokho okuzohlolwa. Ungafaki noma yiziphi izinto ezingabalulekile kukhabethe.

- Ukwenza isivivinyo se-metamerism. Nge-microcomputer, ikhabhinethi ingashintsha phakathi kwemithombo yokukhanya ehlukene ngesikhathi esifushane kakhulu ukuhlola umehluko wombala wezimpahla ngaphansi komthombo wokukhanya ohlukile. Uma ukhanyisa, Vimbela isibani ekukhanyeni njengoba isibani sasekhaya esikhanyayo sikhanyiswa.

- Bhala phansi kahle isikhathi sokusetshenziswa kweqembu ngalinye lesibani. Ikakhulukazi i-D65 standard dlamp kufanele ishintshwe ngemva kokusetshenziswa amahora angaphezu kuka-2,000, ukugwema amaphutha avela esibanini esidala.

- Umthombo wokukhanya kwe-UV wokuhlola izinto eziqukethe idayi ye-fluorescent noma i-whitening, noma ungasetshenziswa ukwengeza i-UV emthonjeni wokukhanya we-D65.

- Umthombo wokukhanya wesitolo. Amaklayenti aphesheya kwezilwandle avame ukudinga omunye umthombo wokukhanya ukuze ahlole umbala. Isibonelo, amaklayenti ase-USA afana namaklayenti e-CWF kanye nawaseYurophu nawaseJapan e-TL84. Kungenxa yokuthi izimpahla zithengiswa ngaphakathi futhi zingaphansi komthombo wokukhanya wesitolo kodwa hhayi ukukhanya kwelanga kwangaphandle. Sekuthandwa kakhulu ukusebenzisa umthombo wokukhanya wesitolo ukuhlola umbala.

- Ukusebenza Kwekhabhinethi Yesibani

-

Ikhabhinethi Yokuhlola Umbala Wemithombo Ekhanyayo Ye-YY6 Engu-6

Mina.Izincazelo

Ikhabhinethi Yokuhlola Umbala, ifanelekela zonke izimboni kanye nezicelo lapho kunesidingo sokugcina umbala ufana futhi usezingeni - isibonelo, Ezezimoto, Eze-Ceramics, Ezezimonyo, Ezokudla, Ezezicathulo, Ifenisha, Ezendwangu ezithungiwe, Ezesikhumba, Eze-Ophthalmic, Eze-Daying, Eze-Packaging, Eze-Printing, Eze-Inks Nezendwangu.

Njengoba imithombo yokukhanya ehlukene inamandla ahlukene okukhanya, uma ifika ebusweni bento ethile, imibala ehlukene iyavela. Ngokuphathelene nokuphathwa kombala ekukhiqizweni kwezimboni, lapho umhloli eqhathanise ukuhambisana kombala phakathi kwemikhiqizo nezibonelo, kodwa kungaba khona umehluko phakathi komthombo wokukhanya osetshenziswa lapha nomthombo wokukhanya osetshenziswa yiklayenti. Esimweni esinjalo, umbala ngaphansi komthombo wokukhanya ohlukile uyahluka. Kuhlala kuletha izinkinga ezilandelayo: Iklayenti likhononda ngomehluko wombala ngisho nokudinga ukwenqatshwa kwezimpahla, okulimaza kakhulu isikweletu senkampani.

Ukuxazulula inkinga engenhla, indlela ephumelela kakhulu ukuhlola umbala omuhle ngaphansi komthombo ofanayo wokukhanya. Isibonelo, i-International Practice isebenzisa i-Artificial Daylight D65 njengomthombo wokukhanya ojwayelekile wokuhlola umbala wezimpahla.

Kubaluleke kakhulu ukusebenzisa umthombo wokukhanya ojwayelekile ukuze uhlukanise umbala ngesikhathi sokusebenza ebusuku.

Ngaphandle komthombo wokukhanya we-D65, imithombo yokukhanya ye-TL84, CWF, UV, kanye ne-F/A iyatholakala kule Khabinethi Yesibani ukuze kutholakale umphumela we-metamerism.

-

(China)YYP103A Imitha Yobumhlophe

Isingeniso somkhiqizo

Imitha Yokugqama/Imitha Yokumhlophe isetshenziswa kabanzi ekwenzeni iphepha, indwangu, ukuphrinta, ipulasitiki,

i-enamel ye-ceramic ne-porcelain, izinto zokwakha, imboni yamakhemikhali, ukwenza usawoti nokunye

umnyango wokuhlola odinga ukuhlola ubumhlophe. Imitha yobumhlophe ye-YYP103A ingahlola futhi

ukucaca kwephepha, ukungabonakali, i-coefficient yokusabalalisa ukukhanya kanye ne-coefficient yokumuncwa kokukhanya.

Izici zomkhiqizo

1. Hlola ubumhlophe be-ISO (ubumhlophe be-R457). Ingaphinde inqume izinga lobumhlophe be-fluorescent lokukhishwa kwe-phosphor.

2. Ukuhlolwa kwamanani e-tristimulus yokukhanya (Y10), ukungabonakali kanye nokucaca. Hlola i-coefficient yokusabalalisa ukukhanya

kanye ne-coefficient yokumuncwa kokukhanya.

3. Lingisa i-D56. Sebenzisa uhlelo lombala olungeziwe lwe-CIE1964 kanye nefomula yokwehluka kombala wesikhala sombala se-CIE1976 (L * a * b *). Sebenzisa ngokubheka izimo zokukhanya kwejiyometri. Ububanzi bebhola lokusabalalisa bungu-150mm. Ububanzi bembobo yokuhlola bungu-30mm noma u-19mm. Susa ukukhanya okuboniswe esibukweni sesampula ngo

izifutho zokukhanya.

4. Ukubukeka okusha kanye nesakhiwo esincane; Iqinisekisa ukunemba nokuqina kokulinganiswa

idatha enomklamo wesekethe othuthukisiwe.

5. Isibonisi se-LED; Izinyathelo zokusebenza okusheshayo ngesiShayina. Umphumela wokubonisa izibalo. Isixhumi esibonakalayo esinobungane phakathi komuntu nomshini senza ukusebenza kube lula futhi kube lula.

6. Ithuluzi lifakwe isikhombimsebenzisi esijwayelekile se-RS232 ukuze likwazi ukubambisana nesofthiwe yekhompyutha encane ukuxhumana.

7. Amathuluzi anesivikelo sokuvala ugesi; idatha yokulinganisa ayilahleki lapho ugesi unqanyulwa.

-

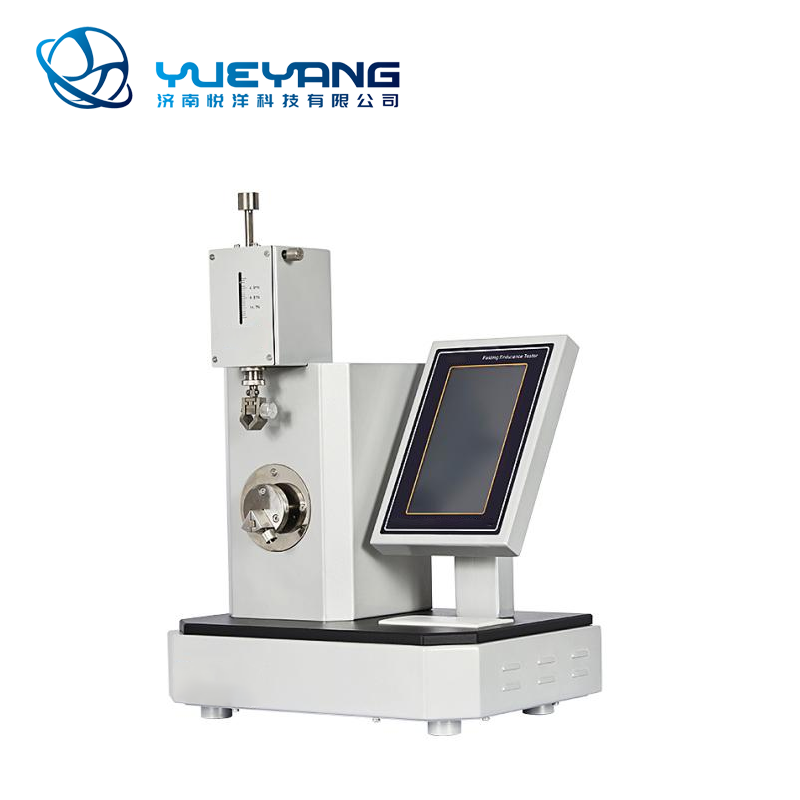

(China) Isivivinyo Sokuqina Kwezicubu ze-YYP-PL - Uhlobo lwe-pneumatic

- Incazelo Yomkhiqizo

Isihloli sokudonswa kwe-tisse i-YYPPL siyithuluzi eliyisisekelo lokuhlola izakhiwo ezibonakalayo zezinto zokwakha

njengokucindezela, ingcindezi (ukucindezela). Isakhiwo esime mpo nesinamakholomu amaningi siyasetshenziswa, futhi

Isikhala se-chuck singasethwa ngokungahleliwe ngaphakathi kobubanzi obuthile. Umugqa wokwelula mkhulu,

Ukuqina kokusebenza kuhle, futhi ukunemba kokuhlolwa kuphezulu. Umshini wokuhlola oqinile ubanzi

isetshenziswa ku-fiber, ipulasitiki, iphepha, ibhodi lephepha, ifilimu nezinye izinto ezingezona ezensimbi ukucindezela okuphezulu, okuthambile

amandla okuvala ukushisa okufakwayo kwepulasitiki, ukuklebhula, ukwelula, ukubhoboza okuhlukahlukene, ukucindezela,

Amandla okuphula i-ampoule, ukuhlubuka kwama-degrees angu-180, ukuhlubuka kwama-degrees angu-90, amandla okugunda kanye neminye imisebenzi yokuhlola.

Ngesikhathi esifanayo, ithuluzi lingalinganisa amandla okudonsa ephepheni, amandla okudonsa,

ukunwebeka, ubude bokuphuka, ukumuncwa kwamandla okudonsa, umunwe okudonsayo

Inombolo, inkomba yokumuncwa kwamandla okudonsa kanye nezinye izinto. Lo mkhiqizo ufanelekela ezokwelapha,

ukudla, imithi, ukupakisha, iphepha kanye neminye imboni.

- Izici Zomkhiqizo:

- Indlela yokuklama ye-instrument clamp engenisiwe iyasetshenziswa ukuze kugwenywe iphutha lokuthola elibangelwe umqhubi ngenxa yezinkinga zobuchwepheshe zokusebenza.

- Isici somthwalo ozwela kakhulu esingenisiwe esenziwe ngokwezifiso, isikulufu se-lead esingenisiwe ukuqinisekisa ukufuduka okunembile

- Ingakhethwa ngokungahleliwe ebangeni lesivinini esingu-5-600mm/min, lo msebenzi ungahlangabezana nokukhishwa okungu-180°, amandla okuphuka kwebhodlela le-ampoule, ukucindezeleka kwefilimu kanye nezinye izibonelo zokutholwa..

- Ngamandla okudonsa, ukuhlolwa kokucindezela kwebhodlela lepulasitiki, ifilimu yepulasitiki, ukunwebeka kwephepha, amandla okuphuka, ubude bokuphuka kwephepha, ukumuncwa kwamandla okudonsa, inkomba yokudonsa, inkomba yokumuncwa kwamandla okudonsa kanye neminye imisebenzi.

- Iwaranti yemoto iyiminyaka emi-3, iwaranti yesensa iyiminyaka emi-5, kanti iwaranti yomshini wonke iwunyaka owodwa, okuyisikhathi eside kakhulu sewaranti eShayina..

- Umklamo wesakhiwo sohambo olude kakhulu kanye nomthwalo omkhulu (500 kg) kanye nokukhethwa kwezinzwa eziguquguqukayo kwenza kube lula ukwanda kwamaphrojekthi amaningi okuhlola.

- Izinga lokuhlangana:

I-TAPPI T494、ISO124、ISO 37、GB 8808、GB/T 1040.1-2006、GB/T 1040.2-2006、GB/T 1040.3-2006、GB/T 1040.4-2006、GB/T 1040.5-2008、GB/T 4850- 2002、GB/T 12914-2008、GB/T 17200、GB/T 16578.1-2008、GB/T 7122、GB/T 2790、GB/T 2791、GB/T 2792、GB/T 17590、GB 15811、ASTM E4、ASTM D882、ASTM D1938、ASTM D3330、ASTM F88、ASTM F904、JIS P8113、QB/T 2358、QB/T 1130、YBB332002-2015、YBB00172002-2015、YBB00152002-2015

-

Isivivinyo Sokuqina Sokuqina Sebhulukwe LaseShayina i-YYP-PL

- Incazelo Yomkhiqizo

Ibhulukwe Elidabula Amandla Okucindezela liyithuluzi eliyisisekelo lokuhlola izakhiwo zomzimba

kwezinto ezifana nokucindezeleka, ingcindezi (ukucindezela). Isakhiwo esime mpo nesinamakholomu amaningi siyasetshenziswa,

futhi isikhala se-chuck singasethwa ngokungahleliwe ngaphakathi kobubanzi obuthile. Ukuqina kokwelula kukhulu, ukuqina kokugijima kuhle, futhi ukunemba kokuhlola kuphakeme. Umshini wokuhlola ukuthambekela usetshenziswa kabanzi ku-fiber, ipulasitiki, iphepha, ibhodi lephepha, ifilimu nezinye izinto ezingezona ezensimbi ukucindezela okuphezulu, ukupakisha kwepulasitiki ethambile amandla okuvala ukushisa, ukudabuka, ukwelula, ukubhoboza okuhlukahlukene, ukucindezela, i-ampoule

Amandla okuphuka, ukuqhekeka kwamadigri ayi-180, ukuqhekeka kwamadigri angama-90, amandla okucheba kanye neminye imisebenzi yokuhlola. Ngesikhathi esifanayo, ithuluzi lingalinganisa amandla okuboshwa kwephepha, amandla okuboshwa, ukunwebeka, ukuqhekeka

ubude, ukumuncwa kwamandla okudonsa, umunwe okudonsayo

Inombolo, inkomba yokumuncwa kwamandla okudonsa kanye nezinye izinto. Lo mkhiqizo ufanelekela izimboni zezokwelapha, zokudla, zemithi, zokupakisha, zephepha kanye nezinye.

- Izici Zomkhiqizo:

- Indlela yokuklama ye-instrument clamp engenisiwe iyasetshenziswa ukuze kugwenywe ukutholakala

- iphutha elibangelwe umqhubi ngenxa yezinkinga zobuchwepheshe zomsebenzi.

- Isici somthwalo ozwela kakhulu esingenisiwe esenziwe ngokwezifiso, isikulufu se-lead esingenisiwe ukuqinisekisa ukufuduka okunembile

- Ingakhethwa ngokungahleliwe ebangeni lesivinini esingu-5-600mm/min, lo msebenzi ungakwenza

- hlangabezana nokukhishwa okungu-180°, amandla okuphuka kwebhodlela le-ampoule, ukucindezeleka kwefilimu kanye nezinye izibonelo zokutholwa.

- Ngamandla okudonseka, ukuhlolwa kokucindezela kwebhodlela lepulasitiki, ifilimu yepulasitiki, ukunwebeka kwephepha,

- amandla okuphuka, ubude bokuphuka kwephepha, ukumuncwa kwamandla okudonswa, inkomba yokudonswa,

- inkomba yokumuncwa kwamandla okudonsa kanye neminye imisebenzi.

- Iwaranti yemoto iyiminyaka emi-3, iwaranti yesensa iyiminyaka emi-5, kanti iwaranti yomshini wonke iwunyaka owodwa, okuyisikhathi eside kakhulu sewaranti eShayina..

- Umklamo wesakhiwo sohambo olude kakhulu kanye nomthwalo omkhulu (500 kg) kanye nokukhethwa kwezinzwa eziguquguqukayo kwenza kube lula ukwanda kwamaphrojekthi amaningi okuhlola.

- Izinga lokuhlangana:

ISO 6383-1、GB/T 16578、ISO 37、GB 8808、GB/T 1040.1-2006、GB/T 1040.2-2006、

I-GB/T 1040.3-2006、GB/T 1040.4-2006、GB/T 1040.5-2008、GB/T 4850- 2002、 GB/T 12914-2008、GB/T 17200、 GB/T 12/T 1620 GB/T 1657/T 1657/8. 2790,GB/T 2791,GB/T 2792,

I-GB/T 17590, i-GB 15811, i-ASTM E4, i-ASTM D882, i-ASTM D1938, i-ASTM D3330, i-ASTM F88, i-ASTM F904, i-JIS P8113, i-QB/T 2358, i-QB/T 1130, i-YBB332002-2015, i-YBB00172002-2015, i-YBB00152002-2015

-

Isivivinyo Sokucindezela Kokupakisha se-(China) YYP-A6

Ukusetshenziswa kwezinsimbi:

Kusetshenziselwa ukuhlola iphakheji yokudla (iphakheji yesoso yama-noodle esheshayo, iphakheji ye-ketchup, iphakheji yesaladi,

iphakethe lemifino, iphakethe lejamu, iphakethe likakhilimu, iphakethe lezokwelapha, njll.) kudingeka kwenziwe ngendlela engaguquki

ukuhlolwa kokucindezela. Amaphakethe e-sauce aqediwe ayi-6 angahlolwa ngesikhathi. Into yokuhlola: Qaphela

ukuvuza kanye nomonakalo wesampula ngaphansi kwengcindezi engaguquki kanye nesikhathi esinqunyiwe.

Isimiso sokusebenza sethuluzi:

Idivayisi ilawulwa yi-touch microcomputer, ngokulungisa ukunciphisa ingcindezi

ivalvu yokwenza isilinda ifinyelele ingcindezi elindelekile, isikhathi sekhompyutha encane, ukulawula

ukuhlehla kwevalvu ye-solenoid, lawula isenzo sokukhuphuka nokwehla kwengcindezi yesampula

ipuleti, bese uqaphela isimo sokuvala sesampula ngaphansi kwengcindezi nesikhathi esithile.

-

(China)YYP112-1 Halogen Moisture Meter

Okujwayelekile:

Isikhathi sokomisa se-AATCC 199: Indlela Yokuhlaziya Umswakama

Indlela Yokuhlola Ejwayelekile ye-ASTM D6980 Yokunquma Umswakama Kumapulasitiki Ngokulahlekelwa Isisindo

Izindlela Zokuhlola ze-JIS K 0068 Ukuqukethwe kwamanzi esitha emikhiqizweni yamakhemikhali

I-ISO 15512 Ipulasitiki - Ukunqunywa kokuqukethwe kwamanzi

I-ISO 6188 Amapulasitiki - Ama-granule e-poly(alkylene terephthalate) - Ukunqunywa kokuqukethwe kwamanzi

I-ISO 1688 Isitashi - Ukunqunywa kokuqukethwe komswakama - Izindlela zokomisa kuhhavini

-

(China) Imitha Yomswakama Yephepha Lokuchitha Imfucuza YYP112B

(Ⅰ)Isicelo:

Imitha yomswakama yephepha likadoti i-YYP112B ivumela ukukala okuqukethwe komswakama kwephepha likadoti, utshani notshani ngokushesha isebenzisa ubuchwepheshe obuthuthukisiwe bamagagasi kagesi. Iphinde ibe nezici zobubanzi bokuqukethwe komswakama, i-cubage encane, isisindo esincane kanye nokusebenza okulula.

(Ⅱ) IZINSUKU ZOBUCHWEPHESHE:

◆Ububanzi Bokulinganisa: 0~80%

◆Ukunemba Kokuphindwa: ± 0.1%

◆Isikhathi sokubonisa: umzuzwana owodwa

◆Ibanga Lokushisa: -5℃~+50℃

◆Ukunikezwa Kwamandla:9V (6F22)

◆Ubukhulu: 160mm×60mm×27mm

◆Ubude beprobe: 600mm

-

Isivivinyo se-(China) se-YY M03 Friction Coefficient

- Isingeniso:

Isihloli se-friction coefficient sisetshenziselwa ukukala i-static friction coefficient kanye ne-dynamic

i-coefficient yokungqubuzana kwephepha, ucingo, ifilimu yepulasitiki kanye neshidi (noma ezinye izinto ezifanayo), ezingaba

ukuxazulula ngqo isici esibushelelezi nesivulekile sefilimu. Ngokulinganisa ubushelelezi

kwezinto ezibonakalayo, izinkomba zenqubo yekhwalithi yokukhiqiza njengokuvulwa kwephakheji

isikhwama kanye nesivinini sokupakisha somshini wokupakisha kungalawulwa futhi kulungiswe ukuze

ukuhlangabezana nezidingo zokusetshenziswa komkhiqizo.

- Izici zomkhiqizo

1. Ubuchwepheshe bokulawula amakhompyutha amancane angenisiwe, isakhiwo esivulekile, ukusebenza kwesikhombimsebenzisi somuntu nomshini okunobungane, kulula ukusisebenzisa

2. Idrayivu yesikulufu eqondile, iphaneli yensimbi engagqwali, isitimela sokuqondisa sensimbi engagqwali sekhwalithi ephezulu kanye nesakhiwo sokuklama esinengqondo, ukuqinisekisa ukuzinza nokuqina kwethuluzi

3. Inzwa yamandla okunemba okuphezulu yaseMelika, ukunemba kokulinganisa kungcono kuno-0.5

4. I-drive yemoto ehlukile enembile, ukudluliselwa okuzinzile kakhudlwana, umsindo ophansi, indawo enembile kakhudlwana, ukuphindaphinda okungcono kwemiphumela yokuhlolwa

Isikrini se-LCD se-TFT esingu-56,500 sombala, isiShayina, isibonisi sejika lesikhathi sangempela, ukulinganisa okuzenzakalelayo, nomsebenzi wokucubungula idatha yokuhlola izibalo

6. Ukukhishwa kokuphrinta kwephrinta encane okusheshayo, ukuphrinta okusheshayo, umsindo ophansi, asikho isidingo sokushintsha iribhoni, kulula ukuyifaka esikhundleni sephepha

7. Idivayisi yokusebenza kwebhulokhi elishelelayo iyasetshenziswa futhi inzwa icindezelwe endaweni eqondile ukuze kugwenywe ngempumelelo iphutha elibangelwa ukudlidliza kokunyakaza kwenzwa

8. Ama-coefficient okungqubuzana anamandla naqinile aboniswa ngedijithali ngesikhathi sangempela, futhi ukushaywa kwesilayida kungahlelwa kusengaphambili futhi kunobubanzi bokulungisa obubanzi

9. Izinga likazwelonke, izinga laseMelika, imodi yamahhala ayikhethwa

10. Uhlelo lokulinganisa olukhethekile olwakhelwe ngaphakathi, okulula ukulilinganisa, umnyango wokulinganisa (umuntu wesithathu) wokulinganisa ithuluzi

11. Inezinzuzo zobuchwepheshe obuthuthukisiwe, isakhiwo esincane, ukwakheka okunengqondo, imisebenzi ephelele, ukusebenza okuthembekile kanye nokusebenza okulula.

-

Isivivinyo Sokumelana Nokugoqa Se-(China) YYP111B

Ukubuka konke:

Ukumelana nokugoqeka kwe-MIT uhlobo olusha lwethuluzi elakhiwe yinkampani yethu ngokusho kwe-

izinga likazwelonke le-GB/T 2679.5-1995 (ukunqunywa kokumelana kokugoqeka kwephepha nebhodi lephepha).

Ithuluzi linemingcele efakiwe esivivinyweni esijwayelekile, ekuguqulweni, ekulungisweni, ekubonisweni,

inkumbulo, ukuphrinta, nomsebenzi wokucubungula idatha, kungathola ngqo imiphumela yezibalo zedatha.

Ithuluzi linezinzuzo zesakhiwo esincane, usayizi omncane, isisindo esilula, ukusebenza okugcwele,

isikhundla sebhentshi, ukusebenza okulula nokusebenza okuzinzile, futhi kufanelekile ekunqumeni

ukumelana nokugoba kwamabhodi ahlukahlukene ephepha.

-

Isivivinyo Sokushelela Okuzenzakalelayo se-YYP 501B (China)

Isihloli sobushelelezi esizenzakalelayo se-YYP501B siyithuluzi elikhethekile lokunquma ubushelelezi bephepha. Ngokusho komklamo wokusebenza obushelelezi wohlobo lwe-Buick (Bekk) lwamazwe ngamazwe. Ekwakhiweni kwemishini, ithuluzi lisusa isakhiwo sokucindezela ngesandla sesando sesisindo se-lever yendabuko, lisebenzisa i-CAM ne-spring ngobuhlakani, futhi lisebenzisa injini ehambisanayo ukuze lijikeleze futhi lilayishe ngokuzenzakalelayo ingcindezi ejwayelekile. Linciphisa kakhulu ivolumu nesisindo sethuluzi. Ithuluzi lisebenzisa isibonisi sesikrini se-LCD esikhulu sombala esithintwayo esingu-7.0 intshi, esinamamenyu esiShayina nesiNgisi. I-interface iyinhle futhi inobungane, ukusebenza kulula, futhi ukuhlolwa kuqhutshwa ukhiye owodwa. Ithuluzi lingeze isivivinyo "esizenzakalelayo", esingasindisa kakhulu isikhathi lapho kuhlolwa ubushelelezi obuphezulu. Ithuluzi linomsebenzi wokulinganisa nokubala umehluko phakathi kwezinhlangothi ezimbili. Ithuluzi lisebenzisa uchungechunge lwezingxenye ezithuthukisiwe njengezinzwa ezinembayo ephezulu kanye namaphampu okuqala angenawoyela angenawoyela. Ithuluzi linokuhlolwa kwamapharamitha ahlukahlukene, ukuguqulwa, ukulungiswa, ukubonisa, inkumbulo kanye nemisebenzi yokuphrinta efakiwe ku-standard, futhi ithuluzi linamakhono okucubungula idatha anamandla, angathola ngqo imiphumela yezibalo zedatha. Le datha igcinwa ku-chip eyinhloko futhi ingabukwa ngesikrini sokuthinta. Ithuluzi linezinzuzo zobuchwepheshe obuthuthukisiwe, imisebenzi ephelele, ukusebenza okuthembekile kanye nokusebenza okulula, futhi liyithuluzi lokuhlola elifanele lokwenza amaphepha, ukupakisha, ucwaningo lwesayensi kanye nezimboni zokuqapha nokuhlola ikhwalithi yomkhiqizo kanye neminyango.

-

Isivivinyo Sokucindezela Ibhokisi le-(China) YYP123C

Izinsimbi Zomculoizici:

1. Ngemva kokuphothulwa komsebenzi wokubuyisela okuzenzakalelayo wokuhlola, hlulela ngokuzenzakalelayo amandla okuchoboza

futhi ulondoloze ngokuzenzakalelayo idatha yokuhlola

2. Izinhlobo ezintathu zesivinini zingasethwa, zonke izixhumi zokusebenza ze-LCD zaseShayina, amayunithi ahlukahlukene ukuze

khetha kusuka.

3. Ingafaka idatha efanele bese iguqula ngokuzenzakalelayo amandla okucindezela, nge

umsebenzi wokuhlola ukupakishwa kokupakisha; Ingasetha ngqo amandla, isikhathi, ngemva kokuqedwa

ukuhlolwa kuvala ngokuzenzakalelayo.

4. Izindlela ezintathu zokusebenza:

Ukuhlolwa kwamandla: ingalinganisa ukumelana okuphezulu kwengcindezi yebhokisi;

Ukuhlolwa kwenani eliqinile:ukusebenza okuphelele kwebhokisi kungatholakala ngokuya ngengcindezi ebekiwe;

Ukuhlolwa kokunqwabelanisa: Ngokwezidingo zezindinganiso zikazwelonke, ukuhlolwa kokufaka inqwaba kungenziwa

ngaphandle ngaphansi kwezimo ezahlukene ezifana namahora ayi-12 namahora angama-24.

III.Hlangana nezinga:

Indlela yokuhlola ingcindezi ye-GB/T 4857.4-92 yamaphakheji okuthutha okupakisha

Indlela yokuhlola ye-GB/T 4857.3-92 yokufakwa kwemithwalo engaguquki yamaphakheji okupakisha nawokuthutha.

-

(I-China)Isilinganiso Selebhu Ye-elekthronikhi ye-YY-S5200

- Ukubuka konke:

Isikali se-Precision Electronic sisebenzisa inzwa ye-ceramic variable capacitance ehlanganiswe ngegolide emfushane

kanye nesakhiwo esisebenza kahle sesikhala, impendulo esheshayo, ukulungiswa okulula, ububanzi besisindo, ukunemba okuphezulu, ukuzinza okungavamile kanye nemisebenzi eminingi. Lolu chungechunge lusetshenziswa kabanzi elabhorethri nasembonini yokudla, imithi, amakhemikhali kanye nomsebenzi wensimbi njll. Lolu hlobo lokulinganisela, oluhle kakhulu ekuzinzeni, olungcono kakhulu ekuphepheni futhi olusebenza kahle endaweni yokusebenza, luba uhlobo oluvame ukusetshenziswa elabhorethri olungabizi kakhulu.

II.Inzuzo:

1. Yamukela inzwa ye-ceramic variable capacitance ehlanganiswe ngegolide;

2. Inzwa yomswakama ezwela kakhulu ivumela ukunciphisa umphumela womswakama ekusebenzeni;

3. Inzwa yokushisa ezwela kakhulu ivumela ukunciphisa umphumela wokushisa ekusebenzeni;

4. Imodi yokukala eyahlukahlukene: imodi yokukala, imodi yokuhlola isisindo, imodi yokukala amaphesenti, imodi yokubala izingxenye, njll.;

5. Imisebenzi ehlukahlukene yokuguqula amayunithi anesisindo: amagremu, ama-carat, ama-ounces kanye namanye amayunithi wamahhala

ukushintsha, okulungele izidingo ezahlukahlukene zomsebenzi wokulinganisa;

6. Iphaneli yokubonisa ye-LCD enkulu, ekhanyayo futhi ecacile, inikeza umsebenzisi ukusebenza okulula nokufunda.

7. Izilinganiso zibonakala ngokuklama okulula, amandla aphezulu, ukulwa nokuvuza, kanye nokungaguquguquki

Impahla kanye nokumelana nokugqwala. Kufanelekela izikhathi ezahlukahlukene;

8. Isixhumi esibonakalayo se-RS232 sokuxhumana okuqondiswe kabili phakathi kwezilinganiso namakhompyutha, amaphrinta,

Ama-PLC namanye amadivayisi angaphandle;

-

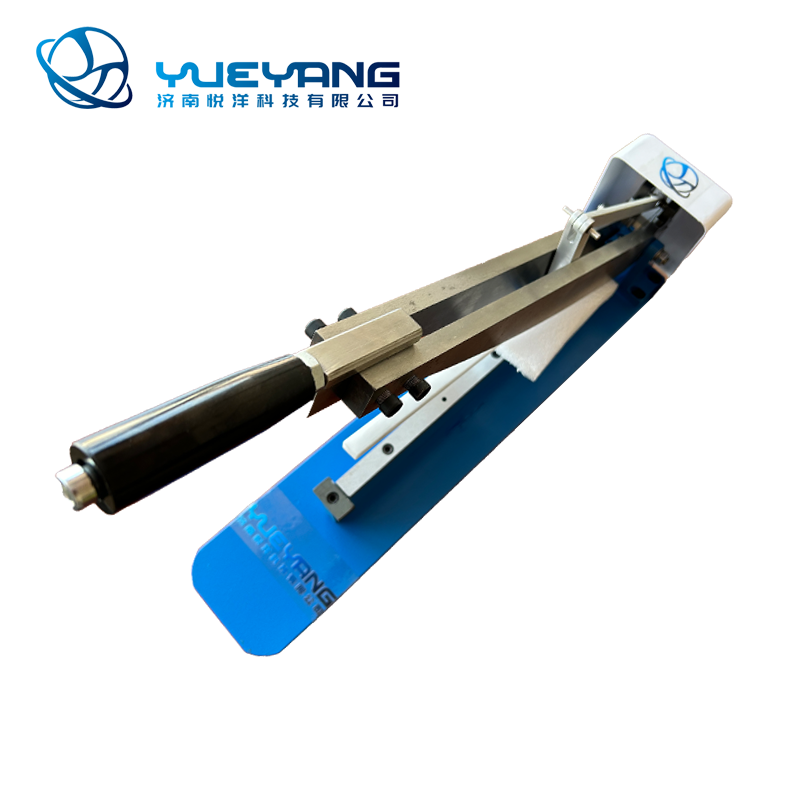

Isivivinyo Sokumelana Nokugoqa Se-(China) YYP111A

- Izicelo:

Umhloli wokumelana nokugoqa uyithuluzi lokuhlola elisetshenziselwa ukuhlola ukusebenza kokukhathala kokugoqa kwe-thin

izinto ezifana nephepha, lapho kungahlolwa khona ukumelana nokugoqeka kanye nokumelana nokugoqeka.

II. Uhla Lokusebenza

Iphepha elingu-1.0-1mm, ikhadibhodi, ikhadibhodi

I-fiber yengilazi engu-2.0-1mm, ifilimu, ibhodi lesifunda, i-foil yethusi, ucingo, njll.

III. Izici zemishini:

1. Imoto ye-loop stepper evaliwe ephezulu, i-Angle yokujikeleza, isivinini sokugoqa sinembile futhi sizinzile.

2. Iprosesa ye-ARM, ithuthukisa isivinini esihambisanayo sethuluzi, idatha yokubala iyasebenza

kunembile futhi kuyashesha.

3. Ilinganisa ngokuzenzakalelayo, ibala futhi iphrinta imiphumela yokuhlolwa, futhi inomsebenzi wokonga idatha.

4. isikhombimsebenzisi esijwayelekile se-RS232, esinesofthiwe ye-microcomputer yokuxhumana (ethengwe ngokwehlukana).

IV. Izinga Lomhlangano:

GB/T 457,QB/T1049,ISO 5626,ISO 2493

-

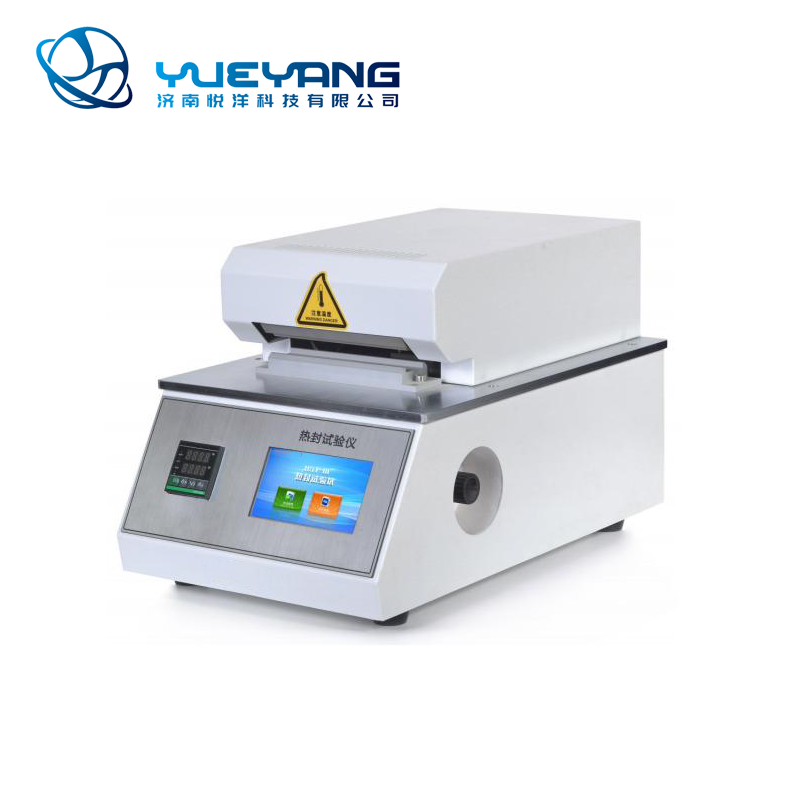

Isivivinyo Sokuvala Ukushisa (China) YY-ST01B

Izinsimbi Zomculoizici:

1. Ukuboniswa kwedijithali kohlelo lokulawula, ukuzenzekela okugcwele kwemishini

2. Ukulawulwa kokushisa kwe-PID yedijithali, ukunemba kokulawula kokushisa okuphezulu

3. Izinto zommese wokuvala oshisayo ezikhethiwe kanye nepayipi lokushisa elenziwe ngokwezifiso, izinga lokushisa lokuvala ukushisa liyafana

4. Isakhiwo sesilinda esisodwa, indlela yokulinganisela ingcindezi yangaphakathi

5. Izingxenye zokulawula umoya ezinembile kakhulu, isethi ephelele yemikhiqizo eyaziwayo emhlabeni jikelele

6. Umklamo ovikela ukushisa kanye nomklamo wokuvikela ukuvuza, ukusebenza okuphephile

7. Isici sokushisa esiklanywe kahle, ukushabalalisa ukushisa okufanayo, impilo yenkonzo ende

8. Izindlela zokusebenza ezimbili ezizenzakalelayo nezisebenzisa ngesandla, zingafeza ukusebenza kahle

9. Ngokwesimiso se-ergonomics, iphaneli yokusebenza ilungiselelwe ngokukhethekile ukusebenza okulula

-

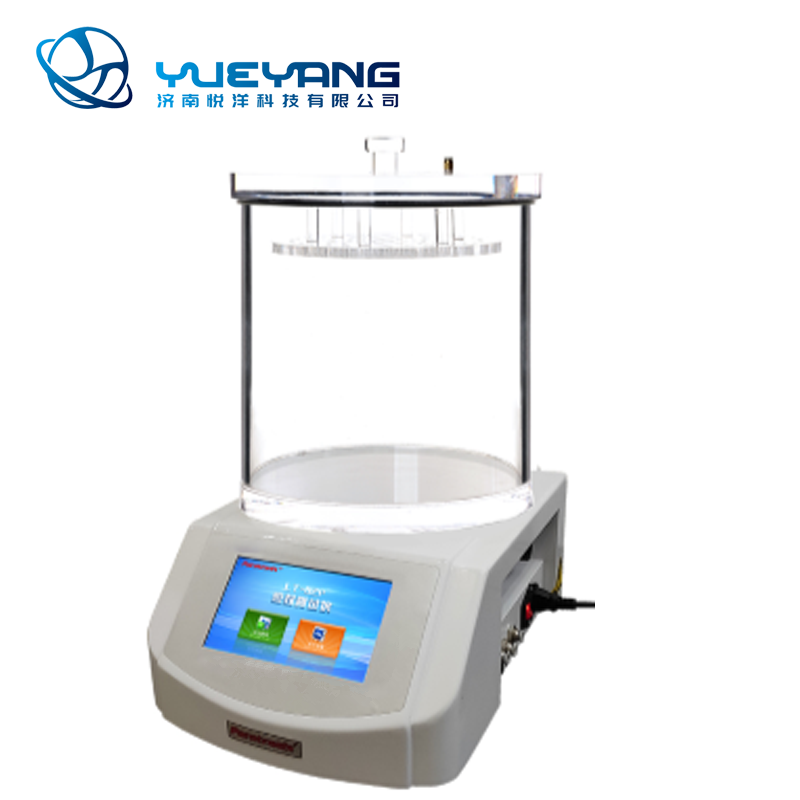

(China) Isivivinyo Sokuvuza se-YYP134B

Isivivinyo sokuvuza se-YYP134B sifanelekela ukuhlolwa kokuvuza kokupakisha okuguquguqukayo ekudleni, emithini,

amakhemikhali ansuku zonke, ama-elekthronikhi kanye neminye imboni. Ukuhlolwa kungaqhathanisa futhi kuhlole ngempumelelo

inqubo yokuvala kanye nokusebenza kokuvala kokupakisha okuguquguqukayo, futhi kuhlinzeke ngesisekelo sesayensi

ukuze kutholakale izinkomba zobuchwepheshe ezifanele. Ingasetshenziswa futhi ukuhlola ukusebenza kokuvala

kwamasampula ngemva kokuhlolwa kokwehla nokucindezela. Uma kuqhathaniswa nomklamo wendabuko,

ukuhlolwa okuhlakaniphile kuyafezeka: ukusetha kabusha kwamapharamitha amaningi okuhlola kungathuthukisa kakhulu

ukusebenza kahle kokuthola; indlela yokuhlola yokucindezela okwandayo ingasetshenziswa ukuthola ngokushesha

amapharamitha okuvuza kwesampula bese ubheka ukukhukhuleka, ukuphuka kanye nokuvuza kwesampula ngaphansi

indawo yokucindezela okunezinyathelo kanye nesikhathi esihlukile sokubamba. Imodi yokunciphisa i-vacuum i-

kufanelekile ukuthola ukuvala okuzenzakalelayo kokupakisha okuqukethwe okunenani eliphezulu endaweni yokuhlanza umoya.

Amapharamitha angaphrintwa kanye nemiphumela yokuhlolwa (ongakukhetha kwiphrinta).

-

(China)YYP114D Isampula Yokusika Enezinhlangothi Ezimbili

Izicelo

Izinamathiseli, Ezinokhonkolo, Amafoyili/Izinsimbi, Ukuhlolwa Kokudla, Ezokwelapha, Ukupakishwa,

Iphepha, Ibhodi Lephepha, Ifilimu Yepulasitiki, I-Pulp, Izicubu, Izindwangu

-

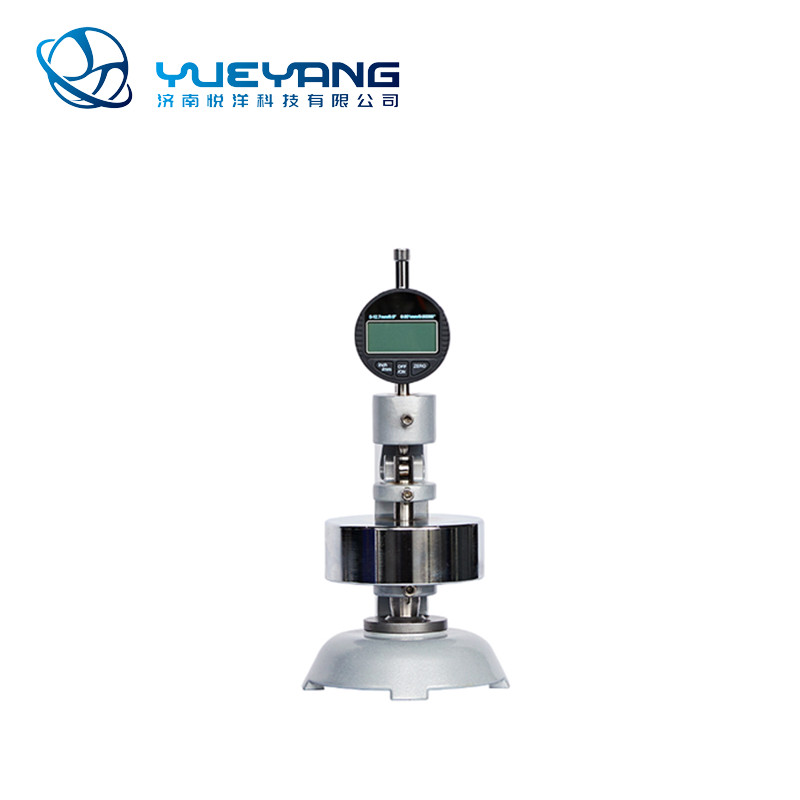

Isivivinyo Sokujiya Kwephepha le-(China) YYP107B

Ibanga Lohlelo Lokusebenza

Isivivinyo Sokujiya Kwephepha sifanelekela amaphepha ahlukahlukene angaphansi kuka-4mm

Izinga Eliphezulu

GB451·3

-

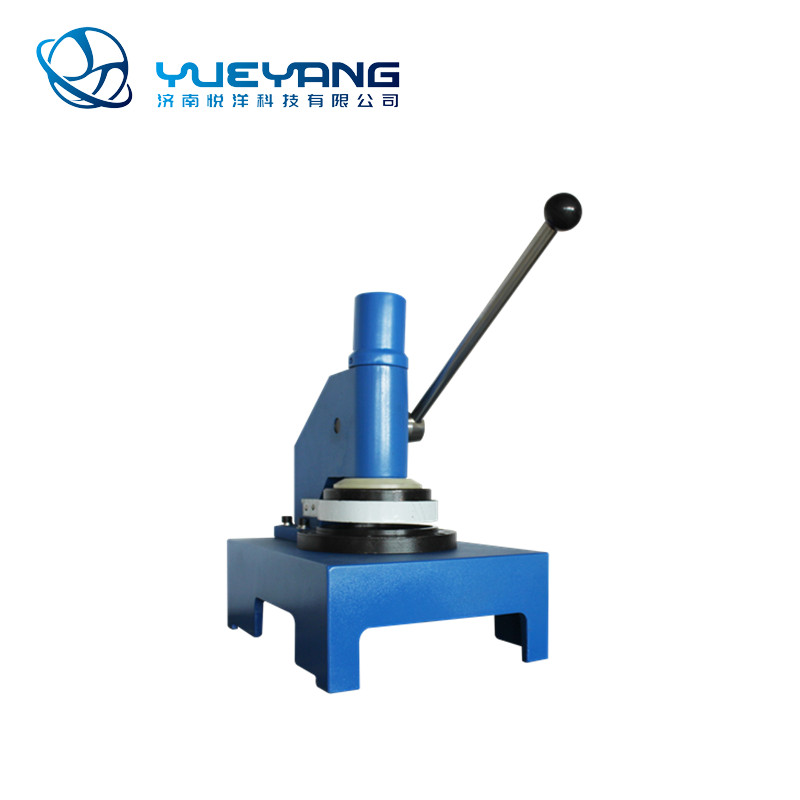

(I-China)YYP114C Isisiki Sesampula Sendilinga

Isingeniso

I-YYP114C Circle sample cutter iyisikhi sesampula sokuhlola zonke izinhlobo zephepha nebhodi lephepha. I-cutter ihambisana nezinga le-QB/T1671—98.

Izici

Njengoba ithuluzi lilula futhi lincane, lingasika ngokushesha nangokunembile indawo ejwayelekile engaba amasentimitha-skwele ayi-100.

-

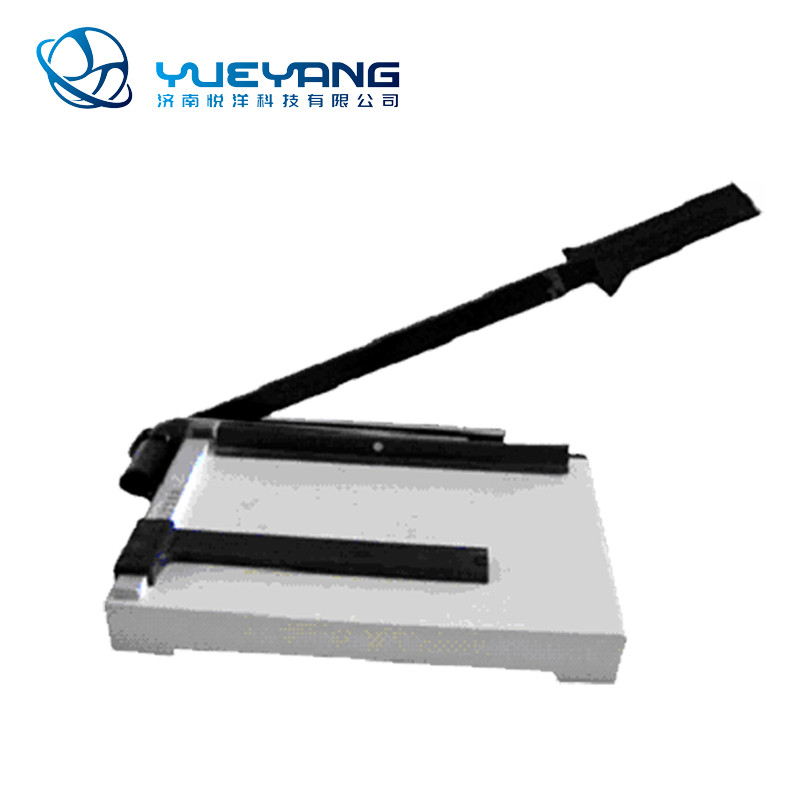

(China)YYP114B Isisiki Sesampula Esilungisekayo

Isingeniso Somkhiqizo

I-YYP114B Adjustable Sample Cutter iyithuluzi elizinikele lokuthola amasampula

ukuhlolwa kokusebenza ngokomzimba kwephepha nebhodi lephepha.

Izici zomkhiqizo

Izinzuzo zomkhiqizo zifaka phakathi ububanzi obukhulu besayizi yesampula, ephezulu

ukucacisa amasampula kanye nokusebenza okulula, njll.