I-Flexible Packaging Tester

-

(I-China) YYP-R2 Isihloli Sokushisa Sokushisa Kokugeza Kawoyela

Isingeniso Sethuluzi:

I-heat shrink tester ifanele ukuhlola ukusebenza kwe-heat shrink yezinto, ezingasetshenziselwa ifilimu yepulasitiki substrate (ifilimu ye-PVC, ifilimu ye-POF, ifilimu ye-PE, ifilimu ye-PET, ifilimu ye-OPS namanye amafilimu okushisa okushisa), ifilimu ehlanganisiwe yokupakisha, Ishidi eliqinile le-PVC polyvinyl chloride, i-solar cell backplane nezinye izinto ezisebenza ngokushwabana kokushisa.

Izici zezinsimbi:

1. Isilawuli se-Microcomputer, isixhumi esibonakalayo sokusebenza kohlobo lwemenyu ye-PVC

2. Idizayini eyenziwe ngabantu, ukusebenza okulula nokusheshayo

3. Ubuchwepheshe bokucubungula isifunda esinembayo esiphezulu, ukuhlolwa okunembile nokuthembekile

4. Ukushisa okuphakathi kwe-Liquid okungaguquki, ububanzi bokushisa bubanzi

5. Ubuchwepheshe bokuqapha izinga lokushisa leDijithali ye-PID abukwazi nje ukufinyelela ngokushesha izinga lokushisa elibekiwe, kodwa futhi bugweme ngokuphumelelayo ukushintsha kwezinga lokushisa.

6. Umsebenzi wesikhathi esizenzakalelayo ukuze uqinisekise ukunemba kokuhlolwa

7. Ifakwe isampula evamile yokubamba igridi yefilimu ukuze kuqinisekiswe ukuthi isampula izinzile ngaphandle kokuphazamiseka kwezinga lokushisa

8. Idizayini yesakhiwo esiqinile, ilula futhi kulula ukuyithwala

-

(e-China) YY174 Air Bath Shrinkage Tester

Ukusetshenziswa kwezinsimbi:

Ingakwazi ukukala ngokunembile nangesilinganiso amandla okuncipha okushisayo, amandla okuncipha okubandayo, nezinga lokuncipha kokushisa kwefilimu yepulasitiki ngesikhathi sokuncipha kokushisa. Ifanele ukunqunywa okunembile kwamandla okunciphisa okushisayo kanye nezinga lokuncipha kwe-thermal elingaphezu kuka-0.01N.

Hlangana nezinga:

I-GB/T34848,

IS0-14616-1997,

I-DIN53369-1976

-

(I-China) YYP2000-D I-Ink Mixer

UyinkiIsingeniso Se-Mixer:

Ukuze uhlangabezane nesidingo semakethe futhi uhlangabezane nezidingo eziphakeme zamakhasimende, inkampani

iklame futhi yakhiqiza isizukulwane esisha se-YYP2000-D mixer. Ukusebenza okulula nokulula;

Isivinini esiphansi, ukuyaluza ngezikhathi ezithile ohlangothini lomgqomo; Idizayini yokugwedla eyingqayizivele yokuxuba, uyinki ungaphendulwa futhi usikwe ngesikhathi sokuxuba, futhi uyinki ungaxutshwa kahle phakathi nemizuzu eyishumi; Uyinki onyakazisiwe awushisi. Ibhakede elilula lokufaka amafutha, (ibhakede lensimbi engagqwali); Isivinini sokuxuba singalawulwa ukuguqulwa kwemvamisa.

-

(I-China) YYP30 Isinamathiseli se-UV Light

Ubuchwepheshe Ipharamitha

Isigaba esisodwa semigqa emithathu 220VAC~ 50Hz

AMANDLA EWONKE

2.2KW

ISISINDO ESIKHULU

100kg

USIZI WAPHANDLE

1250L*540W*1100H

FAKA USIZI

50-100 mm

IBHANDE LE-CONVEYOR

OKUNGANINI IZINSIMBI

IBHANDLA

ISIVIVINYO SEBHANDLA LE-CONVEYOR

1-10m/min

I-UV LAMP

INGCINDEZI EPHEZULU

I-MERCURY LAMP

IBHANDE LE-CONVEYOR UBUNZIMA

300mm

INDLELA YOKUPHOLA

UKUPHOLISA komoya

2KW*1PC

-

(I-China) I-YYP225A Yokuphrinta U-INK Proofer

Amapharamitha wezobuchwepheshe:

Imodeli I-YYP225A I-INK Yokuphrinta Yokuqinisekisa Imodi yokusabalalisa Ukusabalalisa Okuzenzakalelayo (Isikhathi Sokusabalalisa siyalungiseka) Ingcindezi Yokuphrinta Ingcindezi Yokuphrinta ingalungiswa ngokunembile ngokuhambisana nobukhulu bezinto zokuphrinta ezivela ngaphandle Izingxenye Eziyinhloko Sebenzisa Imikhiqizo Edumile Yomhlaba Isivinini Sokusabalalisa Nokuphrinta Isivinini sokusabalalisa nokuphrinta singashintshwa ngokhiye we-shift ngokuya ngezakhiwo zikayinki nephepha. Usayizi 525x430x280mm Irola Yokuphrinta Ubude Obuphelele Ububanzi Obuphelele:225mm (Ubukhulu bokusabalala bungu-225mmx210mm Indawo ye-Color Strip kanye nendawo esebenzayo Indawo yomugqa wombala/Indawo esebenzayo:45×210/40x200mm (imicu emine) Indawo ye-Color Strip kanye nendawo esebenzayo Indawo ye-Colour Strip/ Indawo esebenzayo:65×210/60x200mm (imicu emithathu) Isisindo Esiphelele Cishe ama-75 KGS -

(I-China) YY ST05B Amaphuzu Amahlanu Wokushisa Seal Gradient Tester

Izingeniso:

Umhloli we-heat seal iyithuluzi laselabhorethri elidingekayo lamabhizinisi okudla, amabhizinisi emithi, amabhizinisi emikhiqizo yamakhemikhali yansuku zonke, amabhizinisi okupakisha kanye nokukhiqiza impahla eluhlaza.

Izimo zayo zokusebenza zilingisa ingcindezi, izinga lokushisa kanye nesikhathi somugqa wokupakisha enqubweni yokupakisha yomugqa wokupakisha. Ngethuluzi, impahla ingahlolwa ngokushesha futhi ingasetshenziswa emgqeni wokukhiqiza ngemva kokuhlolwa. Okunye ukusetshenziswa ukushisa uphawu lokupakisha okuguquguqukayo ngaphansi kwezinga lokushisa elibekiwe, ingcindezi kanye nesikhathi, ukuze kube lula futhi ngokushesha.

thola ukushisa okuhle kakhulu kwezinto

Imingcele yenqubo yokubeka uphawu ukuze ihlangabezane nezidingo zabakhiqizi bezinto zokupakisha nokupakisha ukuze kube nemingcele engcono kakhulu yokuvala ukushisa kwezinto.

II.Izinga Lomhlangano:

QB/T 2358(ZBY 28004), ASTM F2029,YBB 00122003

-

(I-China) I-YYP-PL Yebhulukwe Eliklebhula Amandla Aqinile

- Incazelo Yomkhiqizo

I-Trouser Tearing Tensile Strength Tester iyithuluzi eliyisisekelo lokuhlola izakhiwo ezibonakalayo

wezinto ezinjengokushuba, ingcindezi (i-tensile). Isakhiwo esime mpo nesinamakholomu amaningi siyamukelwa,

futhi isikhala se-chuck singasethwa ngokungenasisekelo phakathi kwebanga elithile. I-stroke enwebekayo inkulu, ukuzinza kokugijima kuhle, futhi ukunemba kokuhlolwa kuphezulu. Umshini wokuhlola oqinile usetshenziswa kabanzi ku-fiber, ipulasitiki, iphepha, ibhodi lephepha, ifilimu nezinye izinto ezingezona ezensimbi ingcindezi ephezulu, amandla okufaka uphawu okushisa okushisa epulasitiki, ukudabula, ukwelula, ukubhoboza okuhlukahlukene, ukucindezela, i-ampoule.

amandla okuphuka, ikhasi elingu-180 degrees, ikhasi elingu-90 degrees, i-shear force kanye neminye imiklamo yokuhlola. Ngesikhathi esifanayo, ithuluzi lingakwazi ukukala amandla okuqina ephepheni, amandla okuqina, ukuphakama, ukuphuka

ubude, ukumunca amandla aqinile, umunwe oqinile

Inombolo, inkomba yokumunca amandla aqinile nezinye izinto. Lo mkhiqizo ulungele izimboni zezokwelapha, zokudla, ezemithi, zokupakisha, zamaphepha nezinye.

- Izici Zomkhiqizo:

- Indlela yokuklama yesigxivizo sensimbi engenisiwe yamukelwa ukugwema ukutholwa

- iphutha elidalwe opharetha ngenxa yezinkinga zobuchwepheshe bokusebenza.

- Impahla engenisiwe eyenziwe ngokwezifiso yomthwalo wokuzwela okuphezulu, isikulufu somthofu esingenisiwe ukuze kuqinisekiswe ukususwa okunembile

- Ingakhethwa ngokungafanele kububanzi bejubane obungu-5-600mm/min, lo msebenzi ungakhona

- hlangabezana nekhasi le-180°, amandla okuphulwa kwebhodlela le-ampoule, ukushuba kwefilimu nokunye ukutholwa kwamasampula.

- Ngamandla aqinile, ibhodlela lepulasitiki lokuhlola ingcindezi ephezulu, ifilimu yepulasitiki, ukunwetshwa kwephepha,

- amandla okwephula, ubude bokuphuka kwephepha, ukumuncwa kwamandla aqinile, inkomba yokuqina,

- inkomba yokumunca amandla eqinile neminye imisebenzi.

- Iwaranti yemoto iminyaka emi-3, iwaranti yezinzwa iminyaka emi-5, futhi yonke iwaranti yomshini ingunyaka ongu-1, okuyisikhathi eside kakhulu sewaranti eChina..

- Uhambo olude kakhulu nomthwalo omkhulu (500 kg) idizayini yesakhiwo kanye nokukhetha kwezinzwa eziguquguqukayo kusiza ukunwetshwa kwamaphrojekthi amaningi wokuhlola.

- Izinga lomhlangano:

ISO 6383-1、GB/T 16578、ISO 37、GB 8808、GB/T 1040.1-2006、GB/T 1040.2-2006、

I-GB/T 1040.3-2006、GB/T 1040.4-2006、GB/T 1040.5-2008、GB/T 4850- 2002、 GB/T 12914-2008、GB/T 17200、GB/T 16208 GB 7122, GB/T 2790, GB/T 2791, GB/T 2792,

I-GB/T 17590, GB 15811, ASTM E4, ASTM D882, ASTM D1938, ASTM D3330, ASTM F88, ASTM F904,JIS P8113, QB/T 2358, QB/T 1130, YBB332010102, YBB332010102, YBB30101002,Y201002-2 0152002-2015

-

(I-China) I-YYP-A6 Packaging Pressure Tester

Ukusetshenziswa kwezinsimbi:

Isetshenziselwa ukuhlola iphakheji lokudla (iphakheji ye-noodle sauce esheshayo, iphakheji ye-ketchup, iphakheji yesaladi,

iphakheji yemifino, iphakheji ye-jam, iphakheji yekhilimu, iphakheji yezokwelapha, njll.) idinga ukwenza i-static

ukuhlolwa kwengcindezi. Amaphakethe amasoso ayi-6 aqediwe angahlolwa ngesikhathi. Into yokuhlola: Bheka i-

ukuvuza kanye nokulimala kwesampula ngaphansi kwengcindezi engaguquki kanye nesikhathi esinqunyiwe.

Umgomo wokusebenza wensimbi:

Idivayisi ilawulwa yi-touch microcomputer, ngokulungisa ukwehlisa ingcindezi

i-valve yokwenza isilinda sifinyelele ingcindezi elindelekile, isikhathi se-microcomputer, control

ukuhlehla kwe-valve ye-solenoid, lawula isenzo saphezulu naphansi sengcindezi yesampula

ipuleti, futhi ubheke isimo sokuvala isampula ngaphansi kwengcindezi ethile nesikhathi.

-

(e-China) YY M03 Friction Coefficient Tester

- Isingeniso:

Isihloli se-friction coefficient sisetshenziswa ukukala i-static coefficient kanye ne-dynamic

i-friction coefficient yephepha, ucingo, ifilimu yepulasitiki neshidi (noma ezinye izinto ezifanayo), ezingaba

ukuxazulula ngqo impahla ebushelelezi futhi evula ifilimu. Ngokulinganisa ubushelelezi

yezinto ezibonakalayo, izinkomba zenqubo yekhwalithi yokukhiqiza njengokuvulwa kwephakheji

isikhwama kanye nesivinini sokupakisha somshini wokupakisha singalawulwa futhi silungiswe

ukuhlangabezana nezidingo zokusetshenziswa komkhiqizo.

- Izici zomkhiqizo

1. Ubuchwepheshe obungenisiwe bokulawula amakhompiyutha amancane, isakhiwo esivulekile, ukusebenza kwesixhumi esibonakalayo somshini womuntu onobungane, kulula ukusisebenzisa

2. Idrayivu yesikulufu enembile, iphaneli yensimbi engagqwali, ujantshi womhlahlandlela wensimbi engagqwali wekhwalithi ephezulu kanye nesakhiwo sedizayini esiphusile, ukuqinisekisa ukuzinza nokuqina kwethuluzi.

3. Inzwa yamandla e-American high precision force, ukunemba kokulinganisa kungcono kuno-0.5

4. Ukushayela okunembayo okuhlukile kwemoto, ukudluliselwa okuzinzile, umsindo ophansi, ukuma okunembe kakhudlwana, ukuphindaphindwa okungcono kwemiphumela yokuhlolwa

56,500 isikrini se-LCD sombala we-TFT, isiShayina, isibonisi sejika lesikhathi sangempela, ukulinganisa okuzenzakalelayo, nomsebenzi wokucubungula idatha yokuhlola

6. High-speed micro printer okukhiphayo ukuphrinta, ukuphrinta ngokushesha, umsindo ongaphakeme, asikho isidingo ukushintsha iribhoni, kulula ukufaka esikhundleni umqulu iphepha

7. Idivayisi yokusebenza kwebhulokhi eslayidayo iyamukelwa futhi inzwa igcizelelwa endaweni engaguquki ukuze igweme ngempumelelo iphutha elibangelwa ukudlidliza kokunyakaza kwenzwa.

8. Ama-coefficients ashukumisayo futhi amile aboniswa ngokwedijithali ngesikhathi sangempela, futhi i-stroke yesilayidi ingasethwa kusengaphambili futhi inobubanzi obubanzi bokulungisa.

9. Izinga likazwelonke, izinga laseMelika, imodi yamahhala ingokuzithandela

10. Uhlelo olukhethekile olwakhelwe ngaphakathi, ukukala okulula, umnyango wokulinganisa (inkampani yangaphandle) ukulinganisa ithuluzi

11. Inezinzuzo zobuchwepheshe obuphambili, isakhiwo esihlangene, ukuklama okunengqondo, imisebenzi ephelele, ukusebenza okuthembekile nokusebenza okulula.

-

(I-China) YYP108-10A Umhloli Wokuklebhula Ifilimu

Imibandela yokuklama:

1.ISO 6383-1 amapulasitiki. Ukunqunywa kokumelana nezinyembezi kwamafilimu namashidi. Ingxenye 1: Indlela yokudabula uhlobo lwebhulukwe

2.ISO 6383-2 amapulasitiki. Amafilimu namashidi - Ukunqunywa kokumelana nezinyembezi. Ingxenye 2: Indlela ye-Elmando

3.ASTM D1922 Indlela Yokuhlola Ejwayelekile Yokunqunywa Ukumelana Nokwandiswa Ukuklebhuka kwamafilimu namashidi epulasitiki nge-pendulum Method

4.GB/T 16578-1 Amafilimu namashidi epulasitiki - Ukunqunywa kokumelana nezinyembezi - Ingxenye 1: Indlela yokudabula ibhulukwe

5.ISO 6383-1-1983, ISO 6383-2-1983, ISO 1974, GB/T16578.2-2009, GB/T 455, ASTM D1922, ASTM D1424, ASTM D689, TAPPI T414

UmkhiqizoFizilwane:

1. Uhlelo lulawulwa ikhompuyutha futhi lusebenzisa indlela yokulinganisa ezenzakalelayo neye-elekthronikhi, elungele abasebenzisi ukwenza umsebenzi wokuhlola ngokushesha nakalula.

2. Isampula ye-pneumatic clamping kanye nokukhululwa kwe-pendulum kugwema ngempumelelo amaphutha esistimu abangelwa izici zomuntu.

3. Uhlelo olusizayo lokulungiswa kwezinga lekhompyutha lungaqinisekisa ukuthi ithuluzi lihlala lisesimweni esingcono kakhulu sokuhlola

4. Ifakwe amaqembu amaningi omthamo we-pendulum ukuze ihlangabezane nezidingo zokuhlola ezihlukile zabasebenzisi

5. Isofthiwe yobungcweti isekela ukukhishwa kwedatha yamayunithi ahlukahlukene okuhlola

6. Isixhumi esibonakalayo esijwayelekile se-RS232 sokusiza ukufinyelela kwangaphandle kanye nokudluliswa kwedatha kohlelo

-

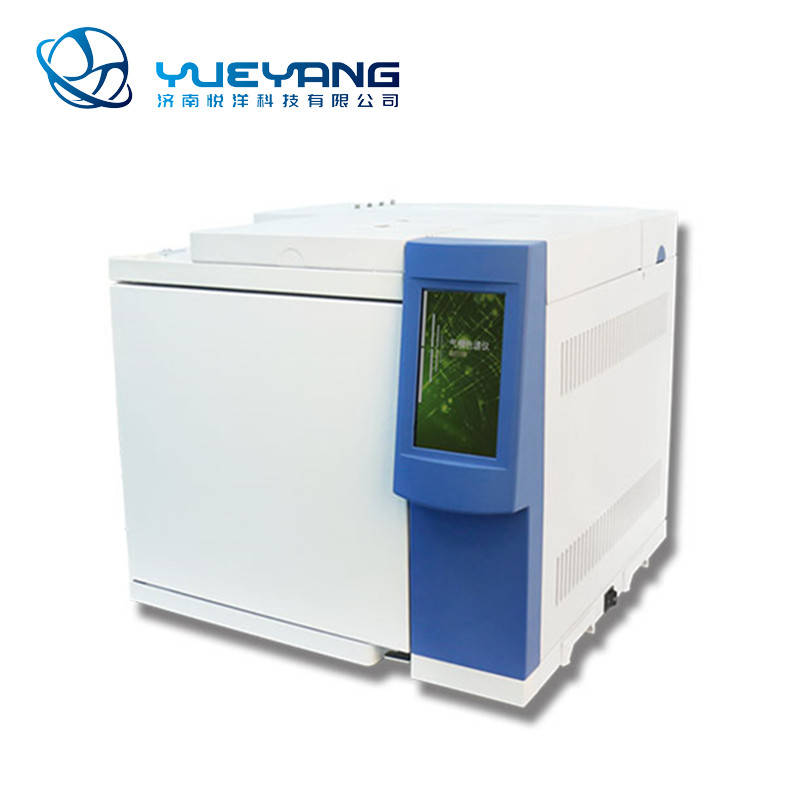

(China)YY112N Gas Chromatograph(GC)

Izici zobuchwepheshe:

1.Isofthiwe yokulawula i-PC ejwayelekile, indawo yokusebenza ye-chromatographic eyakhelwe ngaphakathi, ifinyelela ukulawulwa kwe-PC side reverse

kanye nokulawula i-bidirectional ye-synchronous yesikrini sokuthinta.

2. Isikrini esithintwayo sombala wamayintshi angu-7, isibonisi sedijithali/i-hydrogen/isiteshi somoya (ingcindezi) isibonisi sedijithali.

3. Umsebenzi wokuvikela i-alamu yokushoda kwegesi; Umsebenzi wokuvikela ukulawulwa kokushisisa (lapho uvula umnyangoyebhokisi lekholomu, injini yesifanisi sebhokisi lekholomu kanye nesistimu yokushisisa izovala ngokuzenzakalelayo).

4. Ukuhlukaniswa kokugeleza/ukuhlukana kwesilinganiso kungalawulwa ngokuzenzakalelayo ukuze konge igesi yenkampani yenethiwekhi.

5. Lungiselela ukufakwa kwesampula okuzenzakalelayo kanye nesixhumi esibonakalayo sokuma ukuze kuhambisane nesampula esizenzakalelayo seimininingwane ehlukahlukene.

6.I-multi-core, isistimu ye-hardware eshumekiwe engu-32-bit iqinisekisa ukusebenza okuthembekile kwethuluzi.

7. Umsebenzi wokuqalisa inkinobho eyodwa, namaqembu angama-20 omsebenzi wenkumbulo yemodi yokuhlola eyisampula.

8. Kusetshenziswa i-logarithmic amplifier, isignali yokuthola i-automatic, i-thermal analyzer, njll.)ngesikhathi esifanayo umsingathi kanye nendawo yokusebenza.

9. Inomsebenzi wokuzihlola wesistimu ephelele kanye nomsebenzi wokuhlonza iphutha othomathikhi.

10. Nge-interface yomsebenzi wesandiso semicimbi engu-8 yangaphandle, ingakhethwa ngama-valve ahlukahlukene okulawula umsebenzi,futhi ngokomsebenzi wabo wokulandelana kwesikhathi esimisiwe.

11. Imbobo yokuxhumana ye-RS232 kanye nembobo yenethiwekhi ye-LAM, kanye nokucushwa kwekhadi lokutholwa kwedatha. -

(I-China) YY311-AE3 Isihloli Sokuvumeleka Komphunga Wamanzi (Indlela ye-Electrolytic)

Uhlelo lokusebenza lokuhlola

Isicelo esiyisisekelo

Amafilimu

Ukuhlolwa kokuvuza kwamanzi kwefilimu ehlukahlukene yepulasitiki, ifilimu eyinhlanganisela yepulasitiki, ifilimu eyinhlanganisela yephepha-plastic, ifilimu ye-co-extrusion, ifilimu ehlanganisiwe, ifilimu eyinhlanganisela ye-aluminium foil, ifilimu eyinhlanganisela yengilazi ye-aluminium foil nezinye izinto zolwelwesi. Amashidi

Ukuhlolwa kokuvunguza kwamanzi kweshidi le-PP, ishidi le-PVC, ishidi le-PVDC, ishidi lensimbi ye-foil, ishidi lefilimu, ishidi le-silicon nezinye izinto zeshidi. Iphepha, ibhodi nezinto eziyinhlanganisela

Ukuhlolwa kokungena komhwamuko wamanzi wephepha elimbozwe ugwayi, i-aluminium yephepha - ishidi eliyinhlanganisela yepulasitiki namanye amaphepha nebhodi. Ukupakisha

Ukuhlolwa kokungena komhwamuko wamabhodlela, amabhodlela e-Coke, izigubhu zikawoyela wamantongomane, ukupakishwa kwe-Tetra Pak, izikhwama zokupakisha ze-vacuum, amathini aneziqephu ezintathu, ukupakishwa kwezimonyo, ipayipi lokuxubha amazinyo, izinkomishi zikajeli, izinkomishi zeyogathi nezinye ipulasitiki, iraba, iphepha, inkomishi yephepha, ingilazi. , izinto zensimbi zamabhodlela, izikhwama, amathini, amabhokisi, imiphongolo. Inweba i-applicitoin

Uphawu lwephakheji

Ukuhlolwa kokungena komhwamuko wamanzi kwezikepisi zemikhumbi ehlukahlukene. I-LCD

Ukuhlolwa kokungena komhwamuko wamanzi kwesikrini se-LCD namafilimu ahlobene. I-backplane yamandla elanga

Ukuhlolwa kokungena komhwamuko wamanzi wendiza engemuva yelanga nezinto ezihlobene. Amashubhu

Ukuhlolwa kokungena komhwamuko wamanzi we-PPR namanye amashubhu. Ibhamuza lezemithi

Ukuhlolwa kokungena komhwamuko wamanzi wamabhamuza ekhemisi. Ifilimu yokuvikela amanxeba okubulalayo, isichibi sokhonkolo

Ukuhlolwa kokungena komhwamuko wamanzi amafilimu okuvikela amanxeba angenalutho namapeshi kakhonkolo wezokwelapha. Ukupakisha omakhalekhukhwini

Ukuhlolwa kokungena komhwamuko wamanzi kokupakishwa kwamaselula.